- 9-gallon (34.1 L) capacity meets ANSI Z358.1-2014 requirements for emergency eyewash.

- Constructed from durable high-density green polyethylene for long-lasting use.

- Features ABS plastic eyewash heads with a 0.4 gpm flow rate over 15 minutes for effective flushing.

- Includes a pull-down activation arm for easy operation.

- Designed with a wide-fill opening and threaded cap for easy inspection, cleaning, and filling.

- Equipped with top and side handles for convenient relocation.

- Comes with a J-shaped stainless steel wall bracket for secure mounting and easy removal.

9-gallon (34.1 L) capacity

9-Gallon Capacity Gravity Operated Portable Eyewash Station. Meets ANSI Z358.1-2014 Requirements.

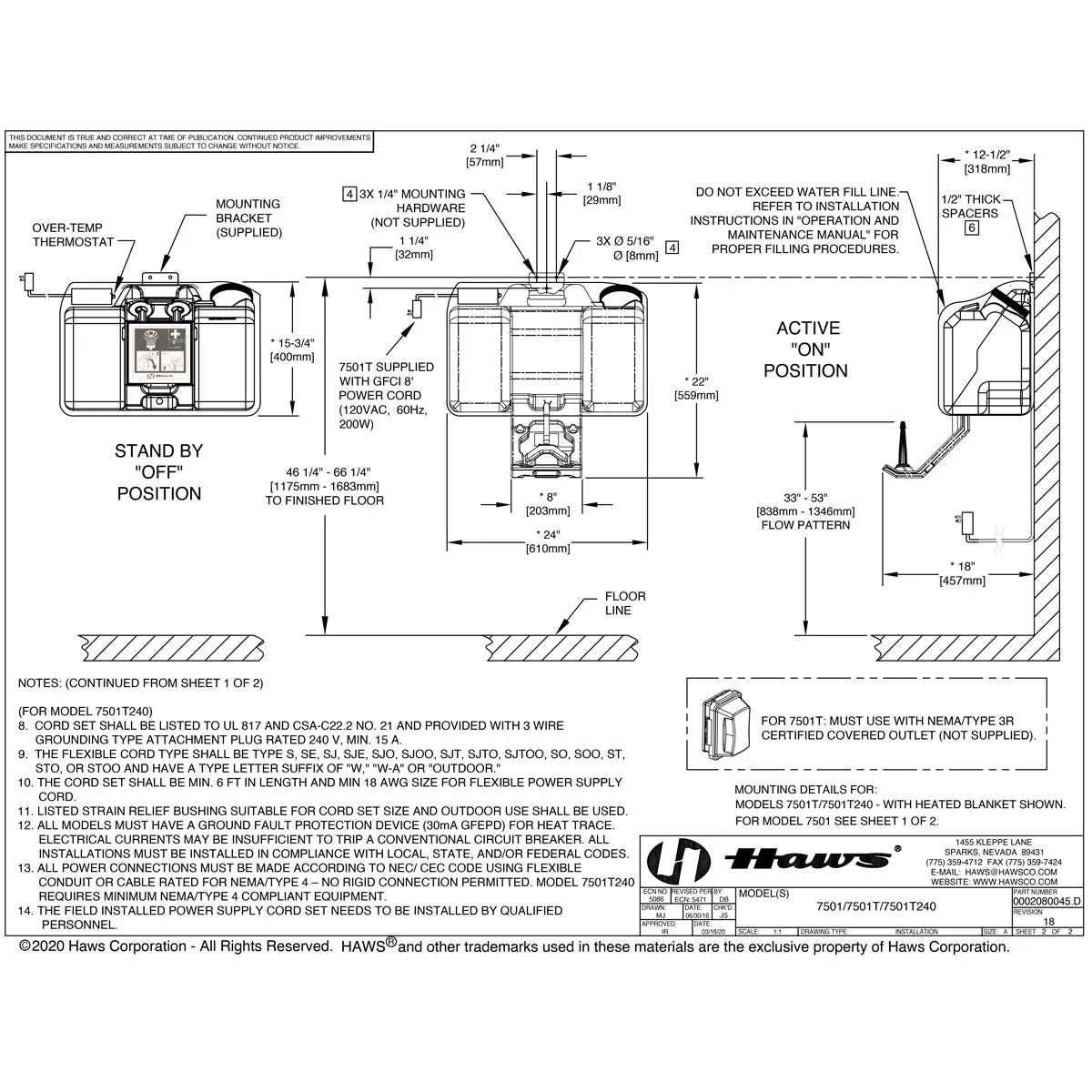

Model 7501 portable gravity operated eyewash shall include a FDA high-density green polyethylene 9-gallon tank, ABS plastic eyewash heads with .4 gpm flow rate over 15 minutes, yellow pull-down activation arm, integral handle on top, wide-fill threaded cap, label-mounted operating and maintenance instructions, stainless steel wall bracket (unit must be hung).

FEATURES & BENEFITS

CONSTRUCTION:

FDA approved high-density green polyethylene tank provides the light and durable construction required in a portable unit.

FLOW CONTROLS:

Pulling down the eyewash arm will begin flushing the 9 gallon (34.1 L) portable tank at .4 gpm (1.5 L) for about 15 minutes, which in turn will create a full patterned flushing of the eyes.

DESIGN:

Tank comes complete with a wide-fill opening and threaded cap for quick inspection, cleaning, and filling. Unit also comes equipped with top and side handles making relocation simple.

MOUNTING:

J-shaped stainless steel wall bracket makes for a well constructed portable mount for easy removal and re-mount.

SPECIFICATIONS

Model 7501 portable gravity operated eyewash shall include a FDA approved high-density green polyethylene 9 gallon (34.1 L) tank, ABS plastic eyewash heads with .4 gpm (1.5 L) flow rate over 15 minutes, yellow pull-down activation arm, integral handle on top, wide-fill threaded cap, label-mounted operating and maintenance instructions, and stainless steel wall bracket (unit must be hung).

APPLICATIONS

Where the eyes of any person may be exposed to injurious or corrosive materials, when suitable facilities for quick flushing of the eyes needs to be provided and a continuous supply of water is not available. Although the 7501 may be installed in a wide variety of locations, it is ideal for the remote and low traffic areas where protective measures are still needed. Emergency eyewash facilities shall be in unobstructed and accessible locations that require no more than 10 seconds for the injured person to reach.